As the Business Development and Technical Manager at Maltha Glasrecycling, I have had the privilege of working closely with Progmatic, and I can say with full conviction that they are an exceptional partner. Progmatic has proven to be a reliable and professional provider of technological solutions for our recycling facilities.

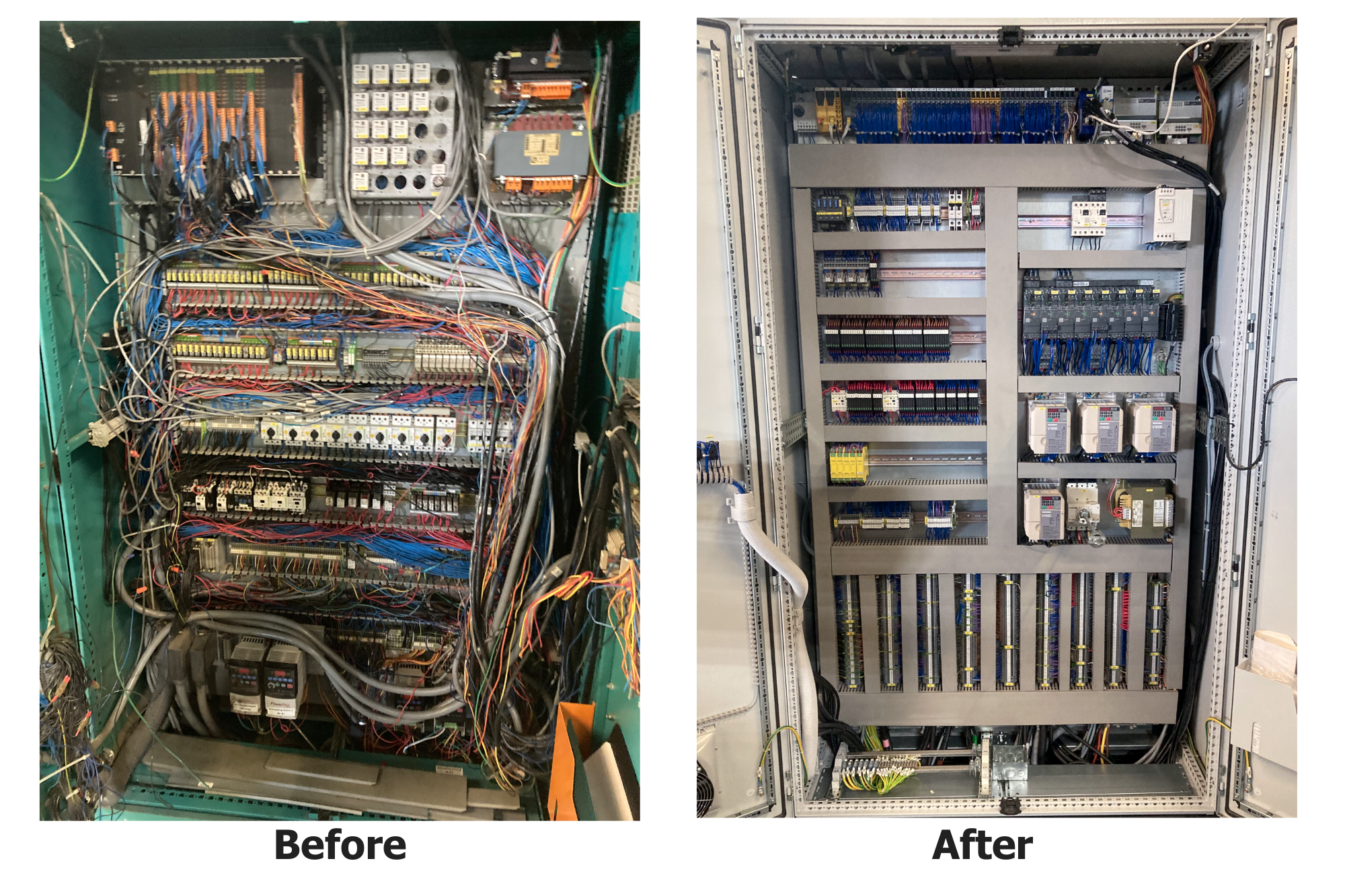

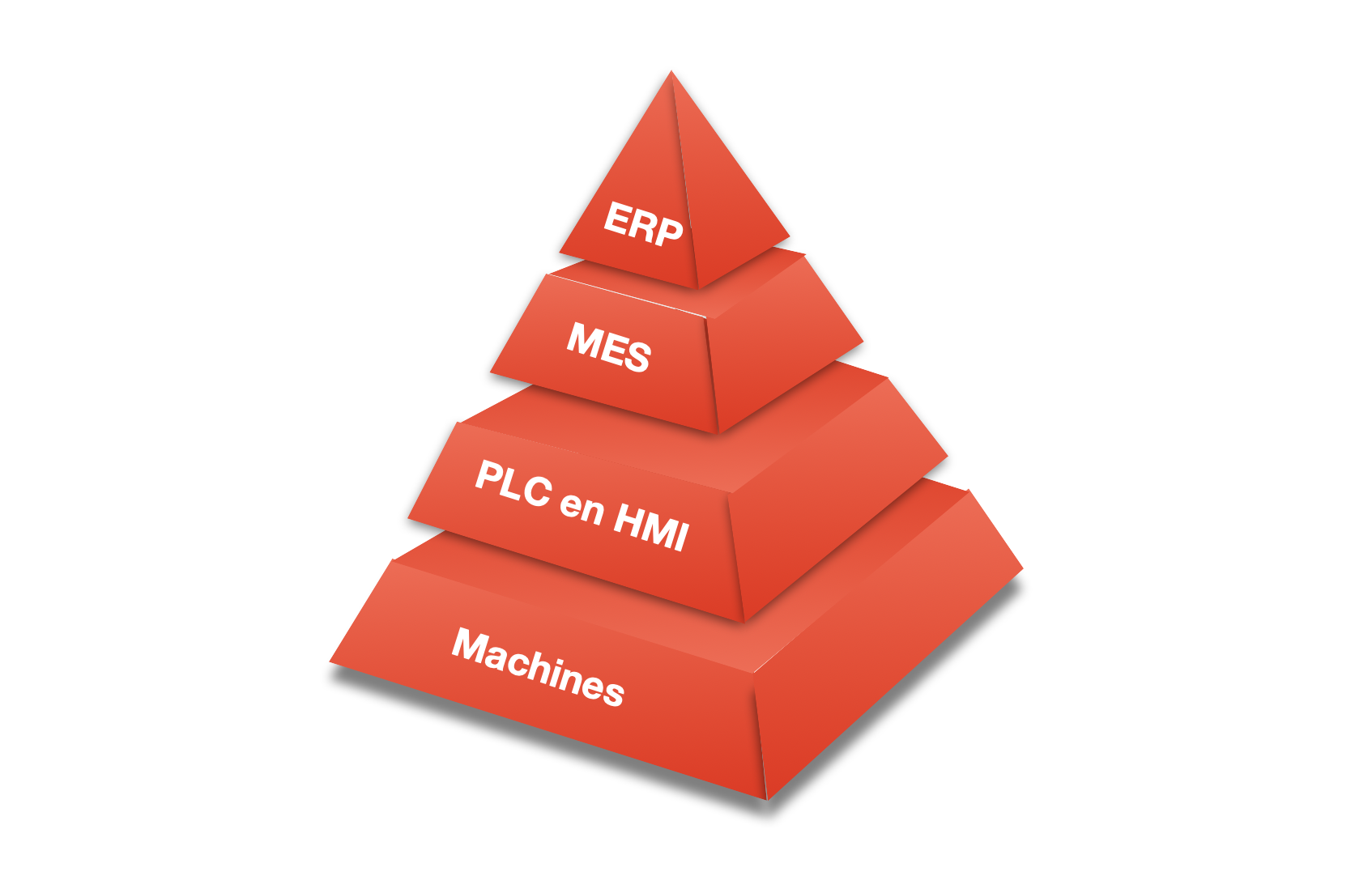

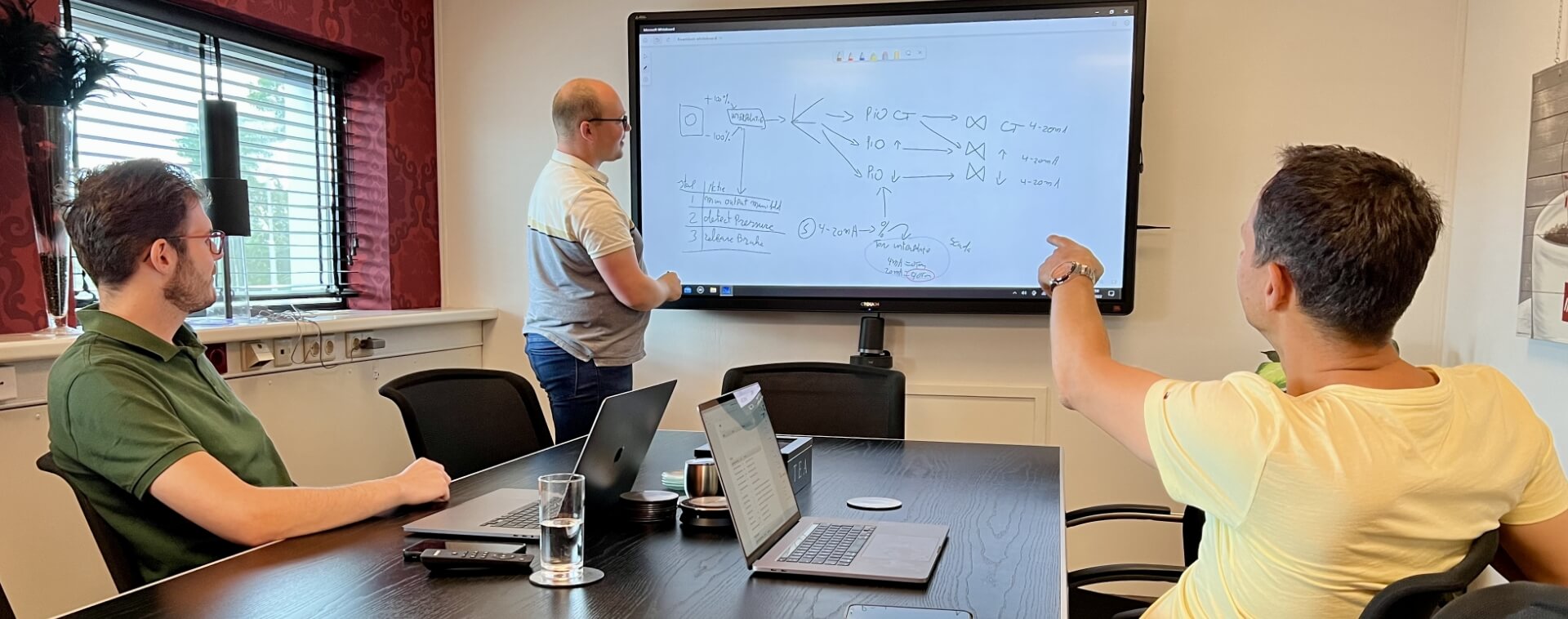

Their dedication to understanding our needs and providing tailored solutions has significantly improved our operational processes. From automated sorting lines to advanced tracking software, Progmatic has helped us increase our efficiency and reduce our environmental impact.

What sets Progmatic apart is not only their technical expertise but also their exceptional customer service. They are always available to answer any questions and provide timely support, even after the implementation of their solutions. This level of commitment and support has given us confidence in their ability to meet our needs and exceed our expectations.

In summary, I wholeheartedly recommend Progmatic to anyone seeking high-quality technological solutions for their recycling business. Their expertise, dedication, and excellent service make them a valuable partner for any organization.