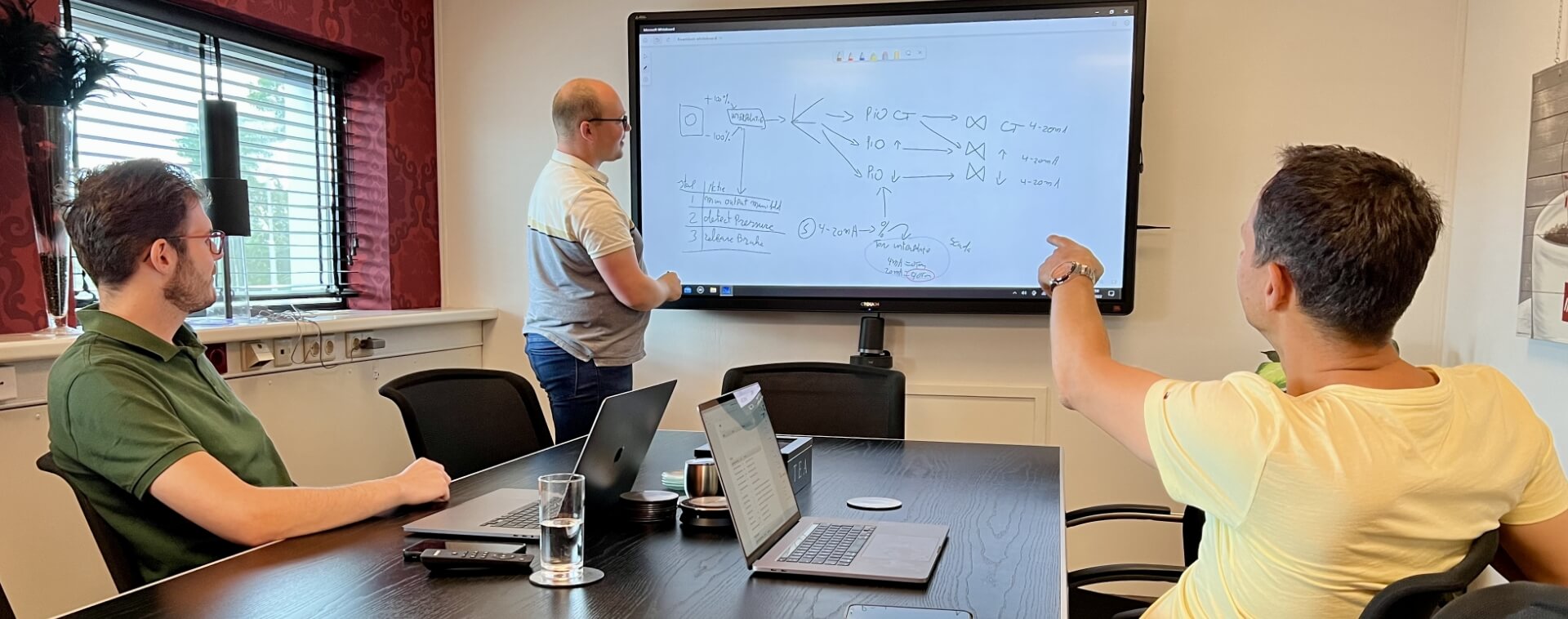

osLaundry concept

When developing and implementing laundry automation, Progmatic optimally utilizes the latest technologies and its own innovations. A great example is the osLaundry concept. This modular concept consists of basic modules and add-on modules. With this solution, raw data from individual machines is collected and streamlined through software, ensuring that the entire process of sorting, washing, drying, ironing, folding, and preparing for transport is automated and runs smoothly.

All osLaundry modules ensure that laundry is processed in the most cost-efficient and sustainable way. Of course, osLaundry offers the possibility to connect to your own MES/ERP system, so your production data can be immediately processed administratively.

The progress of all processes can be monitored remotely through an online application, allowing timely intervention when necessary.