More than 40 years of expertise and experience

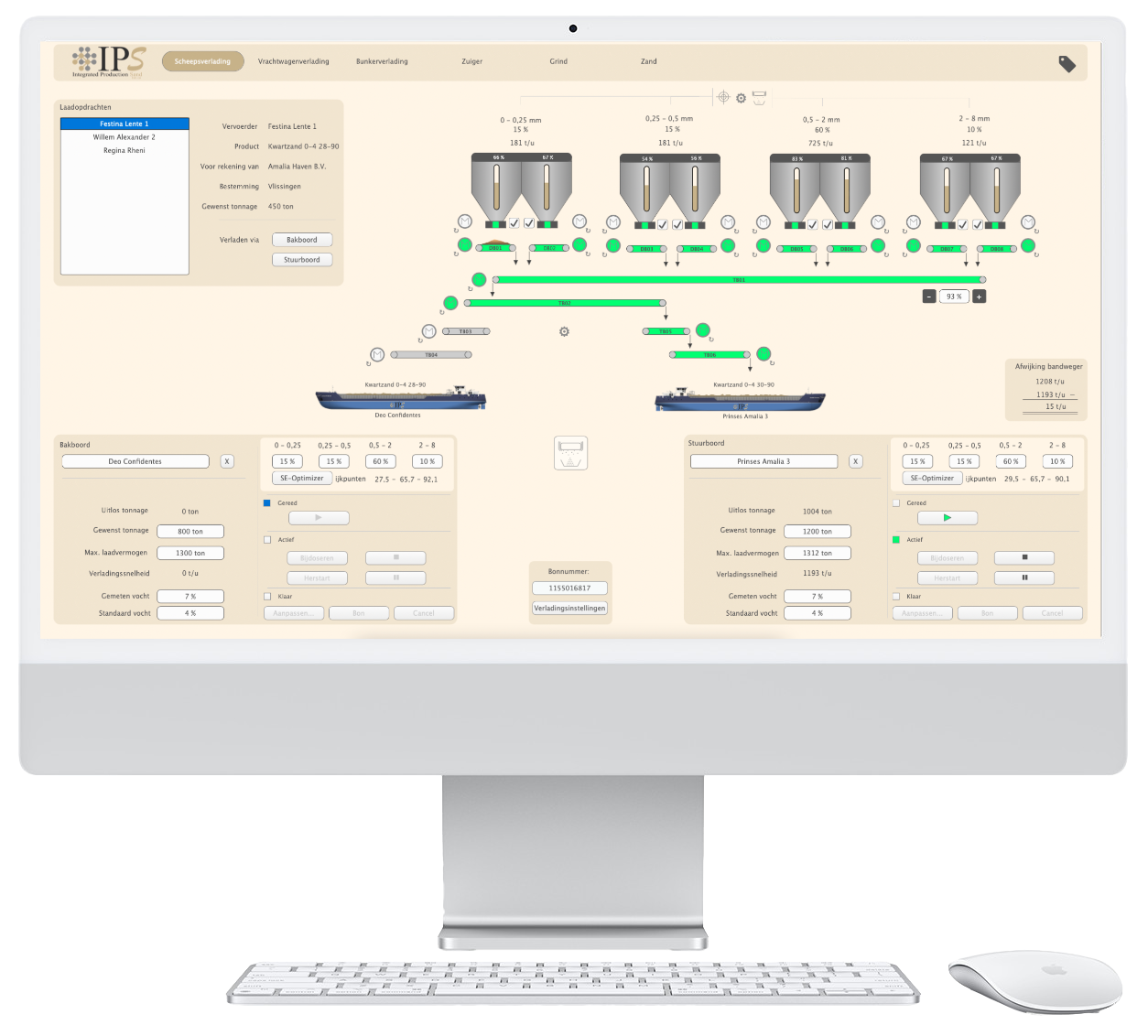

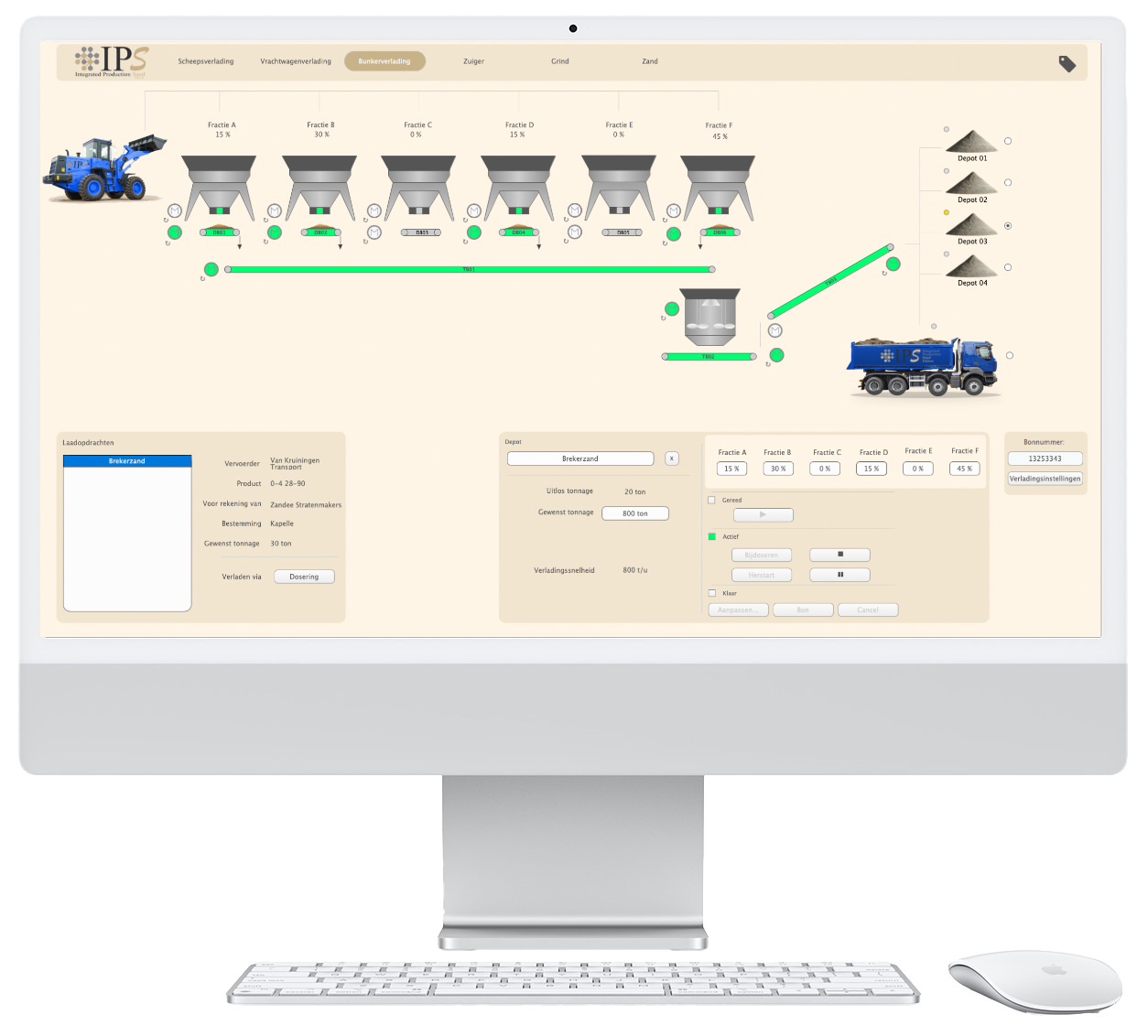

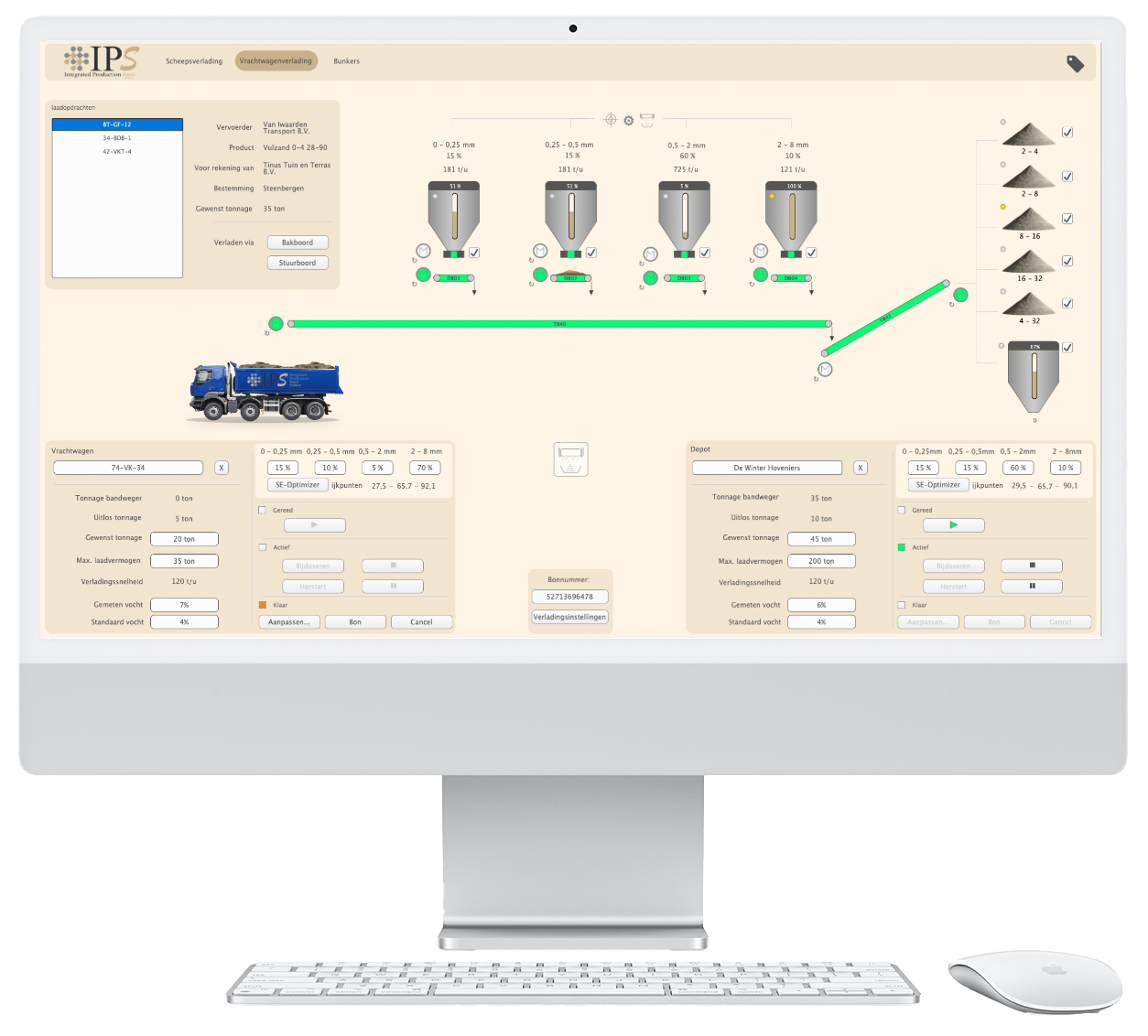

Mining, sand & gravel

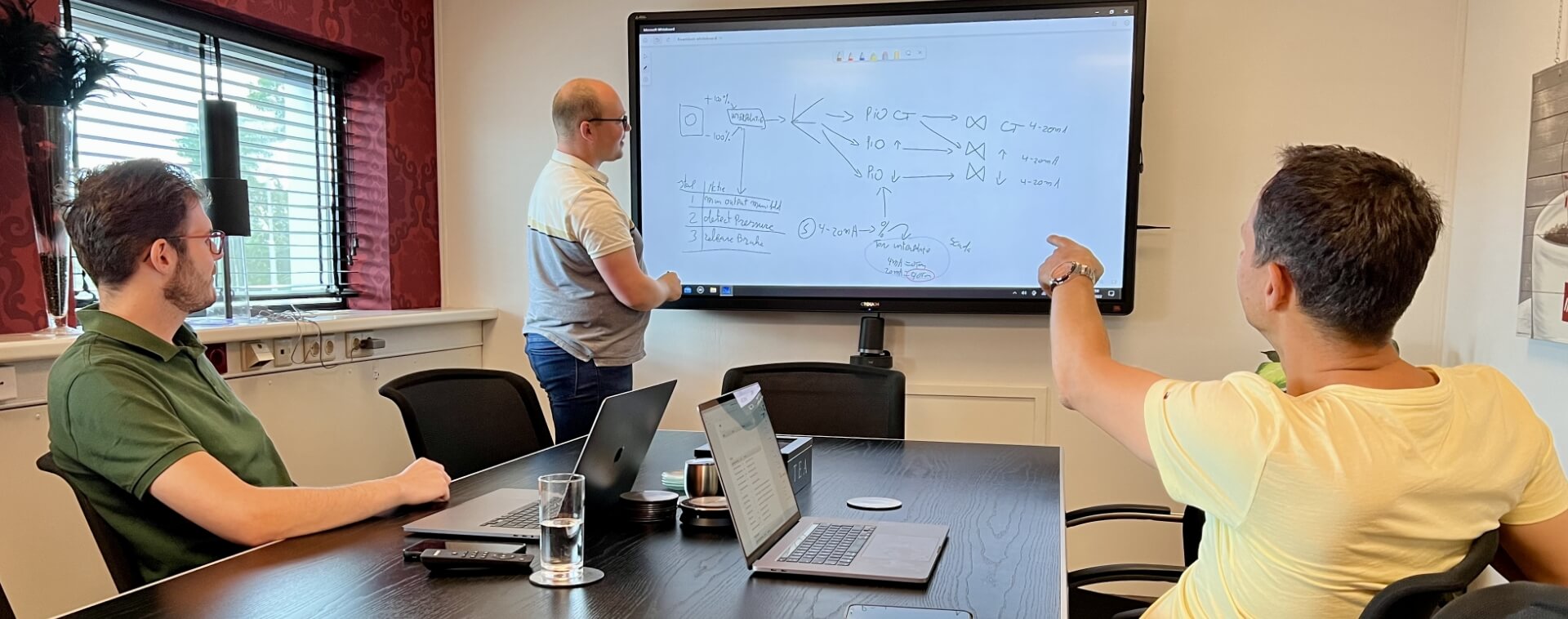

Do you prefer a no-nonsense approach to safety, reliability, and availability of installations under harsh conditions? Progmatic is here for you!

- Practical and flexible setup of your controls

- A lot of knowledge and experience with sand and gravelRaw materials are becoming increasingly scarce.

- Fast, practical support by experienced technicians