Panel building at Progmatic

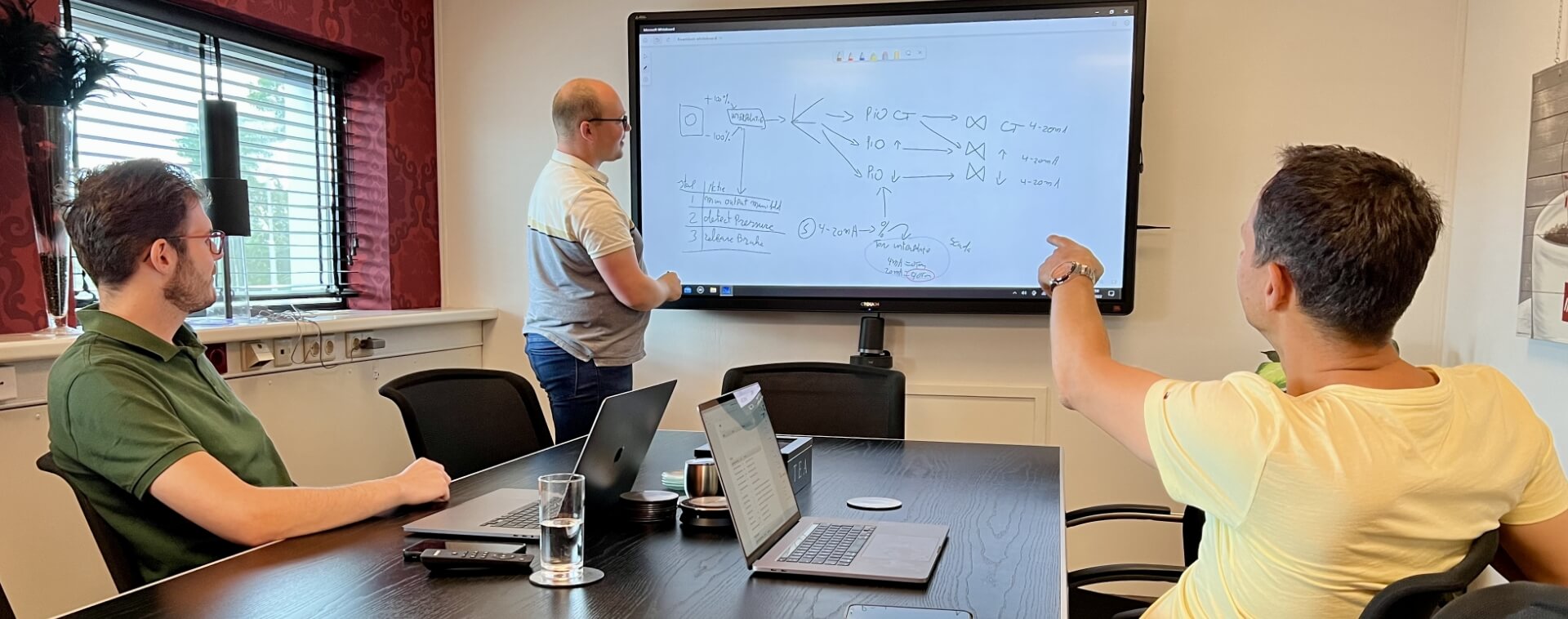

As part of our comprehensive solutions, panel building is crucially important. We have accumulated extensive expertise across various sectors, resulting in craftsmanship in the design, assembly, and finalization of control cabinets. Experienced technicians ensure that each component is configured and integrated with precision.

By meeting applicable standards and requirements and using high-quality components, our control cabinets offer reliability.

Before delivery of the control cabinets, our quality division conducts thorough wiring tests to ensure every connection is correctly made, as well as a functional test. During the functional test, for example, a motor is connected to the frequency converter, parameters are set, and the network is operated. This enhances quality and reduces onsite startup time.

Contact

About us